Angew. Chem. Int. Ed, 2016, 55, 1830-1834

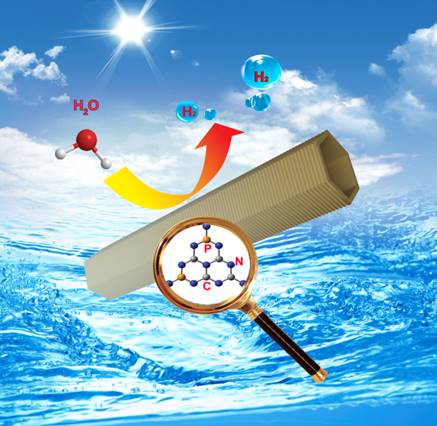

Shien Guo, Baojiang Jiang,* Honggang Fu*. et. al. Phosphorus-Doped Carbon Nitride Tubes with a Layered Micro-nanostructure for Enhanced Visible-Light Photocatalytic Hydrogen Evolution. (Angew. Chem. Int. Ed, 2016, 55, 1830-1834)

Graphitic carbon nitride (g-C3N4, labeled as GCN), as a metal-free organic semiconductor, has attracted increasing attention because it possesses high thermal and chemical stability, and an appealing electronic structure. These unique properties of GCN allow for its diverse applications such as photocatalytic hydrogen evolution, oxygen reduction reaction (ORR), oxygen evolution reaction (OER), etc. Bulk GCN obtained by the direct thermal polymerization process generally yields relatively low surface area and less active sites for GCN, which significantly restricts its applications. Additionally, the quantum efficiency of GCN in the visible light region needs to be further improved. The fabrication of hierarchical micro-nanostructure and heterogeneous element doping for GCN are two effective methods to solve the above problems. Typically, various kinds of micro-nanostructure GCN including porous GCN, sphere GCN, and tubular GCN were obtained through hard-templating approach. Nevertheless, this type of templating is time- and cost-inefficient, for it requires environmentally hazardous reagents to remove the template and prohibits further functionalization. Besides that, the chemical doped GCN with foreign elements, such as phosphorus and sulphur, can tune the energy band structure and conductivity of GCN, thus enhancing the visible-light photocatalytic quantum efficiency as well as improving their surface properties of GCN. This means that the GCN with novel hierarchical micro-nanostructure and simultaneous nonmetal element doping by the template-free method is highly desirable but poses challenge.

Herein, phosphorus-doped hexagonal tubular carbon nitride (P-TCN) with the layered stacking structure was obtained from hexagonal rod-like single crystal supramolecular precursor (Monoclinic, C2/m). The production process of P-TCN involves two steps: 1) the precursor was prepared by self-assembly of melamine with cyanuric acid that from in-situ hydrolysis of melamine under phosphorous acid-assisted hydrothermal condition; 2) the pyrolysis was initiated at the center of precursor under heating, thus giving the hexagonal P-TCN. The hexagonal tube with the layered stack structure significantly increases its specific surface area; as a result, the density of active sites is augmented. Moreover, the introduction of phosphorus decreases the band gap energy, increases the electric conductivity, and suppresses the recombination of photogenerated electron-hole pairs, thus improving the visible-light photocatalytic efficiency for the hydrogen evolution in the presence of sacrificial agents. Thus, the P-TCN exhibited high hydrogen evolution rate of 67 μmol h-1 (0.1g catalyst, λ > 420 nm) in the presence of sacrificial agents, and an apparent quantum efficiency of 5.68 % at 420 nm, better than most of bulk g-C3N4 reported. The hexagonal carbon nitride tube structure is also good carrier material for nanocomposite with specified dimension and chemical functionality.